Coil Tubing Calculations

Every Supervisor and field hand should have an easy access to any and all field calculations they need to operate or forecast a job. Extreme Shale Performance has made all your calculations conveniently available and easy to use. Plug in your job specifications and calculate what you are looking for. Please explore our Operators handbook and see the calculations that are available on your phone or on your laptop, anywhere anytime!

Calculate ID:

OD – (2 * Wall)

1.75 – (2 * .156) = 1.438 in

Calculate Area of Tubing Wall:

( OD2 – ID2 ) * p / 4 NOTE: (p/4 =.7854)

( 1.752 – 1.4382 ) * .7854 = .781 in2

Calculate Tubing Weight Per Foot (Wall Thickness Unknown)

((((OD2 – ID2) * .7854) * 12)/ 231) * 65.5

((((2.8752 – 2.4412) * .7854) * 12) / 231) * 65.5 =

Calculate Tubing Weight per foot:

p * ( OD – Wall ) * Wall * 12 * .2833

p * ( 1.75 – .156 ) * .156 * 12 * .2833 = 2.656 lbs/ft

Calculate Buoyancy Factor:

( 65.447 – Fluid Weight, lbs/gal ) / 65.447

( 65.447 – 8.33 ) / 65.447 = .873

Calculate Weight of Tubing in Fluid:

Weight in Air * Buoyancy Factor

2.656 * .873 = 2.319 lbs/ft

Calculate Load Capacity @ Minimum Yield:

( OD2 – ID2 ) * .7854 * Yield * SF

( 1.752 – 1.4382 ) * .7854 * 80,000 * .8 = 49,997 psi

Calculate Pressure Capacity:

2 * ( Wall – .005 )* Yield / OD

2 * (.156 – .005 ) * 80,000 / 1.75 = 13,806 psi

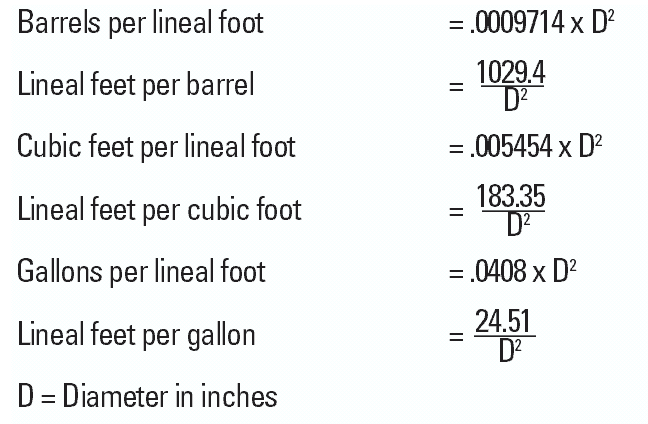

Calculate Pipe Capacity in Barrels per Linear Foot:

ID2 * .0009714

1.4382 .0009714 = .002009 bbls/ft

Multiply by Total Length for Total Capacity in Barrels

Calculate Annular Volume in Barrels per Linear Foot:

(IDprod2 – ODcoil2 ) * .0009714

( 2.4412 – 1.752 ) * .0009714 = .00281316 bbls/ft

Multiply by Total Length for Total Capacity in Barrels

Calculate Annular Velocity, Ft/Min:

GPM * 24.51 / (IDprod2 – ODcoil2 )

84 * 24.51 / ( 4.8922 – 1.752 ) = 98.7 ft/min

Time to Displace:

Total Volume ,bbls / Pump Rate, bbl/min = Minutes

or

Total Volume ,gal / Pump Rate, gal/min = Minutes

Calculate Fluid Pressure Gradient:

Down Hole Pressure / Depth = psi/ft

or

Fluid Weight, lbs/gal * .05195 = psi/ft

Calculate Hydrostatic Pressure:

Weight, lbs/gal * .05195 * Depth

9.6 * .05195 * 11,200 = 5591 psi

Calculate Bottom Hole Pressure:

Well Head Pressure + Hydrostatic Pressure

2200 + ((9.6 * .05195 * 11,200)) = 7785.664 psi

Calculate Kill Fluid Weight:

Weight, lbs/gal + [ Well Head Pressure / ( .05195 * Depth ) ]

9.6 + ( 2200 / ( .05195 * 11,200 ) ) = 13.4 lbs/gal

Calculate Stretch due to Weight in hole, feet :

.0567 * ( Length / 1000 )2

.0567 * (12000 / 1000)2 = 8.1648 Feet

Calculate a “Free Point” for stuck tubing or the length of free pipe

L = Stretch in inches*(30000000*Area)/Force/12

Stretch = inches, from over-pull force

Area = cross-sectional area of CT pipe wall

Force =applied weight over weight of pipe in air to stretch the CT

Example:

CT OD = 1.5

CT ID = 1.282

Stretch = 120 inches

Force = 15000 lbs (Weight Indicator)

120 * 30,000,000 * .476 / 15000 /12 = 9520 feet.

Calculate Elongation Due to Temperature, feet :

Average Temperature :

( Surface Temperature + Bottom Hole Temperature ) / 2

( 70 + 210 ) / 2 = 140 Deg. F

DT :

Average Temperature – Surface Temperature

140 – 70 = 70 Deg. F

Depth * .0000828 * DT / 12

9650 * .0000828 * 70 / 12 = 4.7 ft

Calculate Specific Gravity of oil from API :

141.5 / ( 131.5 + API )

141.5 / ( 131.5 + 30 ) = .876

Calculate thermal gradient, Deg F / ft

(Bottom hole Temperature – Suface temperature) / Depth

( 195 – 60 ) / 9800 = .00138 Deg F / ft

or .138 Deg F / 100 ft

or 1.38 Deg F / 1000 ft

Calculate Pressure drop due to friction

.000077 * MW .8 * Q 1.8 * PV 2 * L / D 4.8

.000077 * 8.33 .8 * 42 1.8 * 1 2 * 10000 / 1.438 4.8 = 613.2 psi

For spooled tubing on the reel: add 10 % or x 1.1

- * 1.1 = 674.5 psi or 67.4 psi /1000 ft

MW = Fluid weight in lbs/gal

Q = Flow rate in gal / min

PV = Plastic viscosity in centipois

L = Length of pipe to flow through in feet

D = Diameter of pipe to flow through in inches

*NOTE: This is conservative compared to the Quality Charts

PHYSICAL CONSTANTS:

Viscosity of water = 1 centipoise

API gravity of water = 10 Deg. API

Fresh water n’ and k’ = 1.0 and .00002

Fresh water weighs 8.33 lbs/gal

1 cu. ft = 7.4805 gal

Water weighs 8.33 * 7.4805 = 62.312565 lbs/cu. ft

1 cu. ft = 12 in * 12 in * 12 in = 1728 cu. in

Pressure = Force / Area

62.312565 lbs / 144 sq in = .4327261458 lbf / sq in / ft or psi/ft

.4327261458 psi/ft / 8.33 lb/gal = .05194791666 (.05195) thus the constant born .052

1 bbl = 5.615 cu. ft = 42 gal

1 gal of Liquid (Cryogenic) N2 expands to 93.11 SCF

N2 expands 697 times ( more exact: 696.4 times)

Calculate KCL in pounds for % Needed:

Gallons x (Fluid weight) x % KCL wanted = lbs

80 bbl x 42 = 3360 gallons

3360 x 8.6 lbs/gal x 2% = 578 lbs KCL

Calculate rate of travel with coiled tubing

(Total bbl ÷ Pump rate in bbls/min = Total Minutes)

(Total Interval in feet ÷ minutes = ft/min)

150 bbls Acid

200 ft Interval to Place Acid

150 bbls÷ 2 bbl/min = 75 mins.

200 ft Interval ÷75 minutes = 2.6 fpm

To make 3 passes using same problem

75 minutes ÷ 3 = 25 minutes

200 ft Interval ÷ 25 minutes = 8 ft/min each pass

To Calculate Pump Rate

(Bore2 x .7854 x Stroke x # of plungers)

42 x .7854 x 8 x 3 = 301.6 in3

= 301.6 in3 x (1gal ÷ 231 in3) x (1 bbl ÷ 42 gals)

= .0312 bbl/rev

= 1 ÷ .0312 = 32.05 rev/bbl

Assume Operating range in the 80 to 90 % Efficiency Range

32.05 rev/bbl x .85% = 27.2 rev/bbl

2 bbl/min x 27.2 rev/bbl = 54.4 strokes/min

Kill Wt Fluid: PPG = PSI / .05195 X depth

(O.D. 2 – I.D. 2) X .7854 X .05195 X 65.447 =

(O.D. 2 – I.D. 2 )X 2.6703 = wt. per ft